FAQ

MOST FREQUENTLY ASKED QUESTIONS

AND THEIR ANSWERS

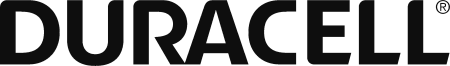

In view of the sensitive electronic components in the vehicle, as a rule starting assistance should only be provided by using a starting assist device.

- Starting assistance from vehicle to vehicle can lead to voltage peaks during disconnection, which can damage or even destroy vehicle electronic systems.

- Therefore, it is essential that the following procedure be strictly observed when using starter cables!

- Standardised starter cables (e.g. in accordance with DIN 72 553) should always be used for giving starting assistance.

- Observe the instructions for use of the starter cables.

- Only connect batteries with the same nominal voltage.

- When connecting the terminals, both vehicle engines must be switched off!

- First connect the two positive terminals 1 with 2. Then connect the negative terminal of the assisting vehicle 3 with 4, the blank metallic point on the vehicle needing assistance, away from the battery. (Observe the instructions of the vehicle manufacturer.)

- Now start the vehicle needing assistance for a maximum of 15 seconds. Do not start the assisting vehicle.

- When disconnecting the terminals, remove the cables in the reverse sequence to the above.

Do not jump-start an electric car!

For technical reasons, the jump-start points of electric cars, if available at all, are not designed to jump-start other vehicles. In this case, it is better to seek the help of a breakdown service. Conversely, however, an internal combustion engine may properly jump-start an electric car.

Jump starting by pushing the car

- Open the driver's window in the car to talk to the people helping.

- Ignition on: Turn ignition key to activate ignition (do not start).

- Driver gives command to push car.

- Driver steps on the clutch, engages second gear (enables smoother starting than with first gear) and remains on the depressed clutch pedal.

- The driver slowly releases the clutch at about 10 km/h and accelerates.

- The pusher continues until the engine starts.

- Everything has worked, the engine starts due to the momentum and you can drive off.

- If the battery is discharged, charging with an external charger is recommended. A few kilometres on the motorway are not enough to fully charge the battery. If you suspect that the starter motor is defective, please visit your trusted specialist workshop at short notice.

Which car can be pushed?

- In principle, any car with a combustion engine, with a manual gearbox and without a catalytic converter.

- Do NOT start all other cars with a catalytic converter or automatic transmission!

In cars with a catalytic converter, unburnt fuel can get into the catalytic converter and cause damage. With automatic transmissions, the torque converter only works when the engine is running, pushing is only possible to move the car from the spot, but not for starting the engine.

- Do NOT push electric cars!

This cannot work, there is no mechanical clutch!

Duracell recommends using only batteries with an open-circuit voltage > 12.50V.

- Before fitting or removing the battery, switch off the engine and all power users.

- Avoid short circuits due to tools.

- When removing the battery, first disconnect the negative (-) terminal and then the positive (+) terminal.

- Prior to fitting the battery, clean the battery compartment.

- Ensure that the battery is secured tightly.

- Clean terminals and battery clips and lubricate lightly with acid-free grease.

- When fitting the battery, first connect the positive (+) terminal and then the negative (-) terminal. Ensure that the clips are secured.

Warning! Always follow the instructions (operating or maintenance) of the vehicle manufacturer!

Should the battery be removed for recharging to avoid damage to the vehicle? Please pay attention to the type of charger. In many cases, valuable tips on charging in the vehicle can be found in the operating instructions of the vehicle manufacturer or in those of the charger manufacturer. In general, fully automatic chargers (charging voltage limitation with 14.8V) are well suited for charging the battery installed in the vehicle.

If your charger has an automatic mode with voltages >15.9V, the battery must be disconnected from the on-board electronics or removed from the vehicle. In the worst case the installed control units could be destroyed by overvoltages, the resulting damage would be enormous!

Attention: Observe the instructions of the vehicle manufacturer when disconnecting.

- Batteries may only be charged with direct current. Connect the positive (+) battery terminal to the positive (+) terminal of the charger, and the negative (-) battery terminal to the negative (-) terminal of the charger.

- Do not switch on the charger until the battery has been disconnected. When charging is completed, switch off the charger before disconnecting the battery.

- It is recommended that the charging current be equal to one tenth of the capacity (e.g. 44Ah divided by 10 = 4.4A charging current).

- The temperature of the acid may not exceed 55°C during charging. If the temperature rises above 55°C, the charging process must be discontinued.

- The fittings must not be opened.

Ensure that recharging amounts to 1.2 times the consumed capacity (e.g. consumed capacity 30Ah, recharge 36Ah) - Charging must be performed in a well-ventilated room.

- Charging is finished when the current drops to 0 or stops falling, or if the automatic charger switches off.

A charging voltage of 16V is recommended for deeply discharged wet batteries (disconnect the battery from the on-board electronics)!

Warning! Oxyhydrogen gas is formed during charging! It is essential that fires, sparks, open flames and smoking be prevented!

Duracell Extreme AGM: only recharge with a voltage controlled charger (max. 14.8V)! The use of standard, non-voltage controlled chargers will destroy the battery through overloading and cause the electrolyte to escape!

Yes, essential.

A conventional starter battery is, as the name suggests, basically designed to provide a high short energy boost to start the vehicle.

As soon as the engine is running, the vehicle's charging system ensures that the energy taken from the battery is recharged and supplies all other electrical loads.

A start/stop battery is responsible for much more than just starting the engine.

Namely to supply the various electrical consumers with energy when the vehicle is stationary, the engine is not running (stops) and the complete on-board power supply including the next starting process must still be ensured!

This means that the technology and components of a start/stop battery differ significantly from those of a conventional starter battery.

Please note:

If a conventional wet battery is installed in a vehicle with start/stop technology, by mistake - due to an allocation error - or due to incorrect cost awareness, a battery breakdown or total failure is pre-programmed. Depending on the driving profile (short distance, stop-and-go,...) a conventional starter battery will be defective within a few months due to the extremely high cyclic load due to the engine start-stop function.

The battery breakdown also leads to the failure of various vehicle functions (including start-stop). Not to mention the customer's annoyance about the battery failure, possible loss of time, waiting for help, delays, scheduling problems and dissatisfaction with the installed spare battery.

Do not install a conventional wet battery in a vehicle with a start/stop function that is equipped with an AGM* or EFB** battery as standard. If necessary, an AGM or EFB battery must be used again - in identical housing and identical performance class.

Duracell Automotive Tip: The Extreme EFB battery can be upgraded to an even more powerful and cycle-resistant Extreme AGM battery in the L3/H6 (70 Ah) and L4/H7 (80 Ah) housing. Please contact your Duracell account manager for more information.

AGM = Absorbent Glass Mat, the acid is absorbed in the glass fleece and thus bound

EFF = Enhanced Flooded Battery, the cycle-proof starter battery

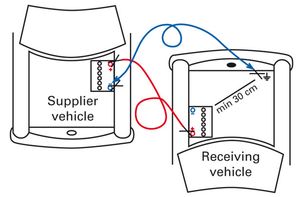

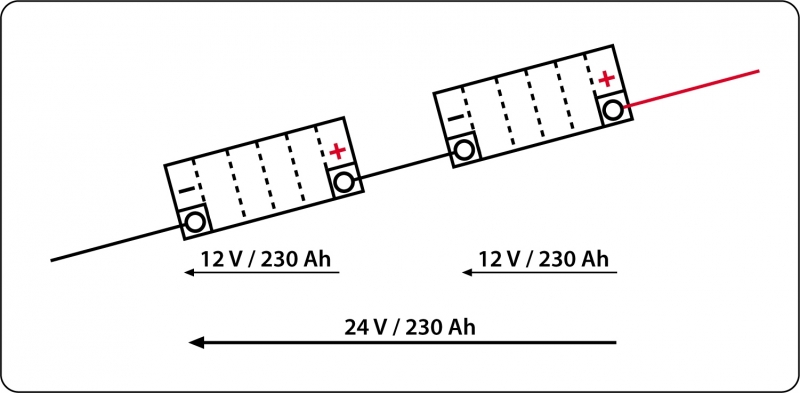

You can calculate the correct capacity for your Duracell Leisure as shown in the following example:

You need a battery for an electrically powered boat. A 600W e-motor is used with a 24V electrical system. In addition, a radio, various navigation lights and a depth sounder have to be supplied with power (total 50W). Five hours of autonomous operation are required.

These values are now used in the following equation:

Wattage: Volt = Ampere x Hours x Safety Factor = Battery Capacity in Ah i.e. 650 : 24 = 27 x 5 x 1.7 = 230Ah (k20)

A safety factor of 70% should be used for wet batteries (30% for AGM and gel recombination batteries).

In this case we would recommend the use of 4 Duracell Leisure DL115 (115Ah each), which you connect serially (2x12V=24V) and in parallel.

The discharge of the battery is probably due to a high quiescent current requirement (>20mA) of the vehicle.

Charge the battery fully with an external charger (voltage limited to approx. 14.8V) and measure the voltage of the battery after a standing time of at least 5 hours.

The measured voltage should be in the range of 12.7 - 12.8V.

If voltage is above this, please switch on the dipped beam of your vehicle for approx. 10 seconds and measure the open-circuit voltage again after a waiting period of approx. 1 minute. If the voltage is below approx. 12.6V, you must restart the charging process.

If your charger has a "recovery mode", the battery must be removed from the vehicle before charging! Otherwise it is possible that the vehicle electronics will suffer irreversible damage due to excessive on-board power supply voltage.

In order to ensure maximum battery life, the following instructions should be followed:

- Keep the surfaces of the battery clean and dry.

- Check the acid levels regularly and if necessary top up with desalinated or distilled water. Never top up with acid. If a substantial water loss occurs, an expert should check the voltage regulator.

- Do not put so-called additives into the battery acid.

- The level of charge of the battery can be checked by means of acid density or open circuit voltage measurement If the density of the acid is below 1.24 or 12,50V kg/l the battery must be recharged .

- In case of saisonal driven vehicles we recommend an external charging twice a year.

In any case, the battery must be fully charged before it is taken out of service.

Duracell Extreme AGM: The state of charge can only be determined by the open-circuit voltage. If the open-circuit voltage is ≤ 12.50 V, the battery must be recharged. An acid density measurement or refilling with distilled water is not permitted - this will destroy the battery.

- Both batteries must be approximately the same age!

- Both batteries should have the same open circuit voltage.

- Both batteries must bear the same type designation!

- The connecting lines should be kept as short as possible.

- Adequate dimensioning of the connecting cables must be ensured.

During series connection the voltages of the individual batteries accumulate.

In order to create a 24 V electrical supply system, two batteries must be connected in series.

Please note:

- Both batteries must have the same type designation.

- Both batteries must be of roughly the same age.

- Both batteries must have the same charge status.

- The connecting lines must have sufficient dimensions and be as short as possible.

- Always exchange both batteries!

Should the aforementioned recommendations not be followed, differing internal resistance of the individual batteries causes a corresponding voltage distribution and thus an asymmetrical load during the loading and discharge phase.

In a parallel connection, the individual capacities and the cold start current of the individual batteries are accumulated.

Please note:

Both batteries must have the same type designation.

Both batteries must be of roughly the same age.

Both batteries must have the same charge status.

The connecting lines must have sufficient dimensions and be as short as possible.

Always exchange both batteries!

Should the aforementioned recommendations not be followed, differing internal resistance of the individual batteries causes a corresponding voltage distribution and thus an asymmetrical load during the loading and discharge phase. As a result, partly high equalizing current flows between the batteries.

Where installation allows, the use of only one battery with a larger capacity is to be recommended

The physical age of the battery has only a very limited informative value about the service life and the state of health of the battery; for this reason, the codes stamped on Duracell batteries do not allow any self-explanatory conclusions to be drawn about the age.

The decisive factor is not the date of production, but the time of commissioning in the vehicle - only then is the starter battery loaded and the electrochemical wear process started.

In the period between production and sale of the battery to the end user, the battery does not "age" if it is kept in a well charged condition, and this is the case with Duracell Batteries and its dealers.

Battery life is much more determined by the number of discharge and charge cycles and the depth of discharge than by the physical age of the battery.

The proof of guarantee and warranty is only the proof of purchase with the date of purchase!

A DOT label with a sequence of numbers, which, for car tyres, among other things, indicates the date of manufacture (DOT=Department Of Transportation USA), is not required for starter batteries!

An AGM battery should be discharged to a maximum of 50% state of charge.

Basically, the deeper the discharge, the shorter the expected service life. An AGM battery can achieve approx. 400 cycles at a discharge depth of 50% (approx. 12.3V open-circuit voltage). Please pay attention to an immediate recharging as soon as an open-circuit voltage limit of approx. 12.5V has been reached.

In order to be able to measure the open-circuit voltage, you should wait for approx. 5 hours after completion of charging, or no discharge has taken place for at least one hour.